Production

In house manufacturing facilities for full operational control

Since our foundation, the Fencor Packaging Group has committed to continuously investing in people, equipment, technology and training to ensure consistent delivery of the highest quality products and services to you as our customer.

Ongoing investment in cutting-edge machinery keeps us at the forefront of innovation and delivering the latest products and practices. As a priority, skilled personnel are trained to be fully conversant in the machinery and equipment to consistently achieve exceptional results.

Over the past decade, we have invested some £10 million in enhancing our manufacturing capabilities, expanding our factory warehouse space, and extending our co-packing function, resulting in plants purposely designed to deliver to the highest standards, so that your brands and products are protected, well placed and positioned in your markets and business objectives are met.

Discuss how our production processes can help you achieve your objectives

Manufacturing Bespoke Corrugated Cardboard Boxes

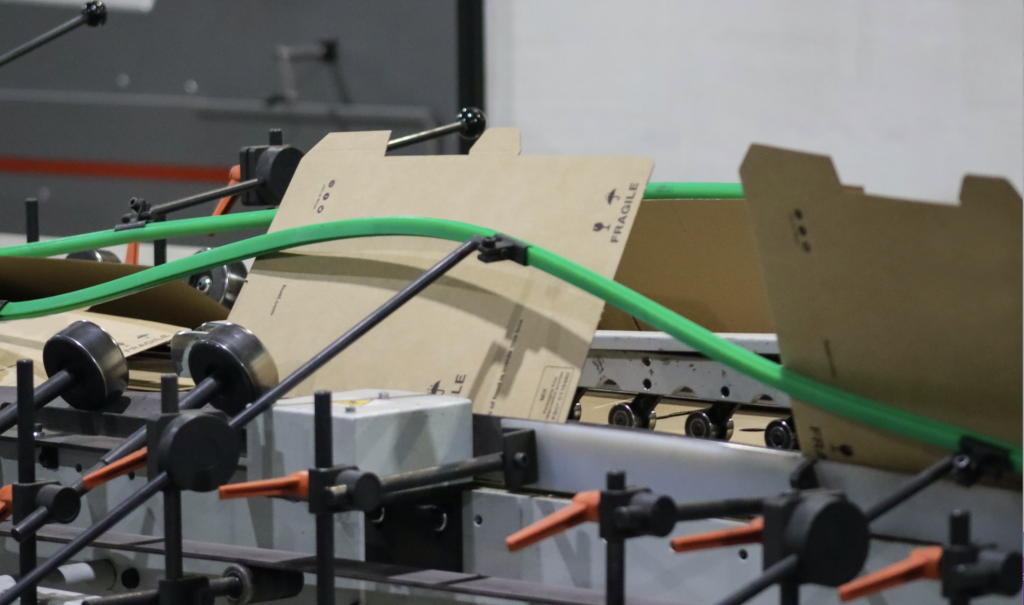

With state-of-the-art “quick set” touch screen case making machines, Manor Packaging produce glued corrugated boxes at a rate of up to18,000 per hour. These advanced machines convert corrugated board into printed, slotted, glued, and bundled corrugated boxes in a matter of seconds. Your bundled boxes are then automatically palletised and ready for distribution to any location you require.

Investment in three BOBST machines, known as the Rolls Royce of our industry, have further enhanced our machine capabilities. These BOBST machines include a 4-color case maker with a rotary die cutter, vision cut flatbed die cutter, and expert fold A2 multipoint gluer.

Brand representation in today’s market places is critical, so the most accurate and effective technology needs to be employed to ensure your brand colours are consistently exact on all cardboard packaging. It is so important that the tolerances adhered to at Manor Packaging are 33% higher than the industry average at +/- 2 Delta.

However, we didn’t stop at investing in machinery. To maximise effective, accurate, production output, we also completely overhauled our ink supply and processes, installing a brand new, state-of-the-art ink kitchen. An Innovex 14 pump ink dispenser was installed linked to a computer controlled Xrite iColour checker, which utilises Xrite ink formulation software for precise, exact colour making and checking.

Find out how our attention to delivering accuracy can help you.

Social Media

Constantly updated with informative and interesting content.