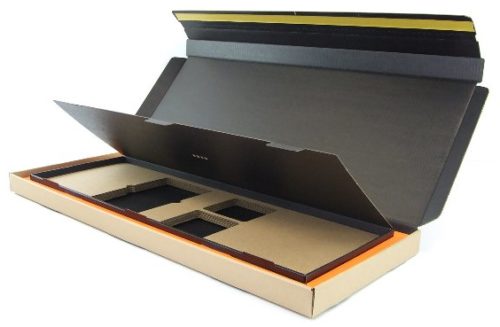

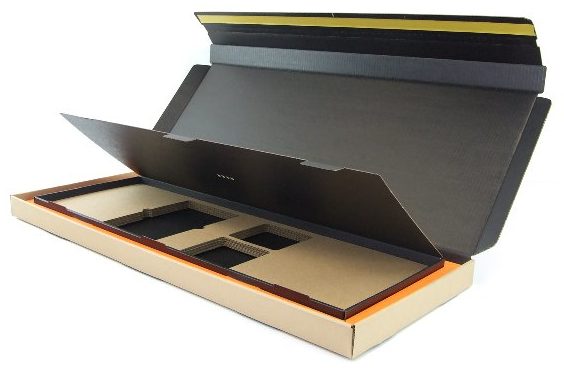

Die Cut Cardboard Boxes

Bespoke die cut packaging to enhance the unboxing experience

The die cut process enables us to create more complicated, detailed and custom die cut boxes. Die cutting tools ensure a level of consistency across the production process and achieve a high quality finish.

What is Die-Cut Packaging?

Die-cutting is a manufacturing process that uses a specialised tool, known as a die, to cut a specific shape out of a material like corrugated cardboard. Think of it like a cookie-cutter for boxes. This technique allows for the creation of intricate and precise designs that standard box cut methods cannot achieve. The process starts with a digital design, or dieline, which is then used to create the physical die. This precision ensures that every die cut box is identical, providing consistent quality packaging for your business.

The Manor Packaging design team have been designing die cut corrugated box solutions for over 35 years and have evolved in line with new technologies to have the knowledge and experience to help you achieve more from your packaging range.

The in-house design team’s expertise in print and structural engineering means that they can use CAD drawing techniques to create millimetre precise boxes and inners to hold and protect your product based on exact internal dimensions. It’s these correctly packaged and protected goods that give peace of mind when shipping, eliminate damaged deliveries during transit, and reduce the need for excessive handling.

The Manor Packaging team always structurally design pack solutions to be materially efficient. By not using excess materials this helps you save money, and is also more sustainable for the environment too.

It doesn’t just have to be practical either, the team will work with you to develop the most visually appealing look and feel either using existing brand guidelines or from a product and brief. We can incorporate your logo, specific colour palettes, and branding to create large die cut printed boxes that stand out.

The Benefits of Custom Die-Cut Boxes

- Precision Protection: Custom-engineered die-cut inserts and wall boxes are designed to the exact specification of your product. This snug fit holds items securely, eliminating movement and the need for excessive void fill like bubble wrap, which is crucial for protective packaging of valuable or delicate goods.

- Enhanced Unboxing Experience: First impressions matter, especially in e-commerce. A well-designed, easy-to-assemble die-cut box enhances the customer experience, making your brand more memorable.

- Sustainability: By designing to the exact size required, we minimise material waste. Our precision die-cut inserts are a durable and fully recyclable alternative to plastic vacuum-formed trays.

- Versatility and Functionality: From sturdy shipping boxes to intricate display cartons, the versatility of die-cutting is unmatched. We can create boxes with self-locking flaps, crash-lock bases, or specific lid designs to suit any need, often removing the need for packing tape to seal the box.

Technical Specifications & Flute Profiles

To ensure your die cut boxes offer the right level of durability, we utilise various material grades and flute profiles. Choosing the right “wall” thickness is vital for performance:

- E-Flute (approx. 1.5mm): Ideal for high-quality printing and smaller retail boxes where a fine finish is required.

- B-Flute (approx. 3mm): The most common single wall flute, offering a balance of crush resistance and stacking strength.

- Double Wall (BC or EB): Combines two layers of fluting for heavy-duty protection, perfect for transport and heavier items.

Our Design and Prototyping Process

Creating the perfect template for your packaging is a collaborative process. We can work from a PDF or DXF file, or our team can create a custom dieline for you.

- Consultation: We discuss your product, measurement requirements, shipping needs, and brand requirements.

- Digital Design: Our structural designers create a 2D dieline and a 3D mockup to visualise the final product.

- Prototyping: We produce a physical sample for you to test and approve before committing to a full production run to make sure the die is perfect.

Popular Die-Cut Box Styles

While the customisation options are nearly limitless, one of the most popular styles is the FEFCO 0427. This robust mailer box style features a hinged lid and interlocking flaps or tabs that slot together to create a durable, easy-to-assemble carton. The 0427 style is perfect for e-commerce shipments and subscription boxes, offering a secure and professional packaging solution. These boxes are available in different sizes to suit your specific product range.

Applications Across Industries

The precision engineering of die-cut packaging makes it suitable for a wide range of products and industries:

- Ecommerce & Retail: Used extensively for parcel boxes, gift boxes, and packaging for beauty products, luxury confectionery, and more.

- Advanced Manufacturing & Engineering: We create heavy-duty pallet packaging with custom die-cut inserts to protect precision components, aerospace assemblies, and medical equipment from shock and vibration.

- High-Performance Motorsport: Our team designs robust transit cases with precision inserts to cradle individual components like carbon fibre parts and sensitive electronic control units.

Stock and Serve: De-risking Your Supply Chain

Manor Packaging operates a “Stock and Serve” facility to support your operational efficiency. Instead of ordering small batches frequently, we can manufacture larger runs of your custom die cut boxes to achieve economies of scale. We then hold this stock in our secure warehousing facilities, allowing you to “call off” stock for next-day delivery. This model liberates your warehouse space and ensures you never run out of essential packaging.

Frequently Asked Questions

How do I measure a die cut box?

Always measure the internal dimensions (Length x Width x Depth) of the box. This ensures your product fits snugly inside the single wall or double wall structure without damage.

Can you print on the inside of the box?

Yes, we can customise the interior to enhance the unboxing experience. Adding colour or instructions inside is a popular trend for e-commerce brands.

What is the minimum order quantity?

We offer bespoke solutions and can discuss volume requirements based on your specific needs, whether you need a small run or a large stock-and-serve arrangement.

To discuss your corrugated cardboard packaging options please contact us and we’ll be pleased to help.

Why Choose Manor Packaging?

- We manufacture box solutions using our own manufacturing facility. This ensures we can oversee all aspects of customer projects from concept through to delivery

- A consultative approach is taken for each project to understand all aspects of your corrugated packaging needs

- We are specialists in structural box design, understanding packing automation, palletisation and developing box solutions that deliver supply chain efficiencies

- With shareholding in corrugated sheet manufacturer CorrBoard, there is an assurance of continued supply

- Our ‘on-time and in full’ delivery performance maintains an average between 95% and 98% (Anything over 95% is deemed to be world class)

- All Manor packaging’s corrugated board is 100% recyclable, made from recycled and sustainable forestry materials

- All sustainable forestry materials are FSC®-certified

To discuss your corrugated cardboard packaging options please contact us and we’ll be pleased to help.

Social Media

Constantly updated with informative and interesting content.