Crash Lock Boxes vs Standard Cardboard Boxes: A Practical Guide for Faster Packing and Reduced Waste

High-volume fulfilment operation and assembly lines depend on fast, repeatable and consistent box assembly. When your team needs to meet strict delivery targets, the choice between a generic cardboard box and a crash lock box directly impacts your labour hours, material waste, and daily throughput. Inevitably, your company performance.

What is the Mechanical Difference Between Standard and Crash Lock boxes?

The construction of the base determines each box’s assembly method and the speed at which your team can work, the board grade options can remain identical between both styles and often be improved:

Standard Cardboard Boxes (FEFCO Style 0201)

The FEFCO 0201 style is the standard shipping carton and is a Regular Slotted Container (RSC) usually with a glue seam, manufactured from a single sheet of corrugated board. The flaps meet in the middle but don’t interlock, meaning their structural integrity relies on manual labour time and packing tape, your packer must fold the bottom flaps. Due to the reliance on packing tape, the standard box format is 99.9% recyclable.

Crash Lock Boxes (FEFCO Style 0713)

Crash lock boxes are die-cut containers with a multi-point glued base. We supply these flat boxes with a reduced footprint to an RSC. Your packers simply need to press the opposite corners together, and the base will automatically lock into place, with no tape or additional tools are required.

How Does Assembly Time Differ?

Speed is the primary operational difference between box styles, and when your order volumes rise every second counts. Crash-lock boxes can be assembled significantly faster than standard RSC cases, reducing your workers’ box assembly times remarkably, reducing operational packing time.

Crash lock formats will help your packing team maintain consistent throughput during seasonal peaks. And, with faster assembly and no need for using packing tape on the base flaps, your operation can process more orders without the need to bring in temporary labour.

Why do Crash Lock Boxes Cost More to Buy but Less to Use?

Crash lock boxes have a higher purchase price per unit because manufacturing involves die-cutting and multi-point glueing. However, high-volume operations will reduce the total operating cost significantly through impressive efficiency gains in your operations department.

Labour Cost Reduction

Reducing assembly time saves many seconds of paid labour per package. So, if your facility ships 1,000 orders per day, this can save several hours of labour daily in high-volume fulfilment environments.

Material Savings

Standard boxes require tape on the top and bottom, while crash lock boxes require no tape for the base and very often, the top of the box can be redesigned to avoid tape altogether. Many bespoke e-commerce packaging solutions also include an integrated peel-and-seal strip for the lid. This eliminates tape costs and removes the time your team would spend changing tape gun rolls. It also enables the box to be returnable, ideally suited for the e-commerce sector.

Volumetric Efficiency

We design crash lock boxes that support variable heights, which means your packers can fold the box down to the exact height of the contents. This right-sizes your packaging approach, will reduce your messy and wasteful void fill usage and lower courier charges based on volumetric weight.

How does Box Choice Affect Sustainability and Waste?

As a part of our philosophy of Intelligent and Sustainable Corrugated Packaging, we’ll help you align your logistics with your environmental & sustainability goals:

Tape Reduction

Off the shelf standard boxes depend on plastic tape for their structural integrity, and while the board is recyclable, the tape introduces plastic into your waste stream. Crash lock boxes function without base tape, which creates a 100% recyclable mono-material pack, free from plastic contamination. The exclusion of base tape, and the fact that there is no adhesive contamination on the board fluting also make it easier for your customers to return to a flat state and recycle.

Carbon Neutral Board Manufacturing

We source all of our corrugated sheet board from CorrBoard UK, a facility that uses an on-site Anaerobic Digestion (AD) plant. This plant converts organic food waste into energy to power the corrugator, and consequently, the manufacturing process of the raw material (the corrugated board) is carbon neutral.

Materials and Targets

- Recycled Content: Our corrugated packaging typically contains 80% recycled content and 20% from FSC®-certified sustainable sources.

- Net Zero: Fencor is committed to achieving net zero carbon emissions by 2030 in Scopes 1 and 2.

What are the Benefits for Your Brand and Unboxing?

Your packaging is often the first physical touchpoint for your customer, and your brand’s critical first impression. Crash lock boxes offer a cleaner presentation than a taped RSC, and the absence of tape provides an uninterrupted canvas suitable for high-quality branding.

We offer high-quality 4-colour flexographic printing options and print to colour tolerances of ±2 Delta E (ΔE), which is 33% tighter than the industry standard. Printing is available on both the exterior and interior to create a shareable “wow” moment for unboxing. The integrated tear strips also create a user-friendly opening experience, so your customers don’t need to fetch knives that could damage the product and detract from the opening experience.

How Does This Impact Health and Safety?

Manual taping involves repetitive wrist and arm motions, with gripping a dispenser and twisting to cut tape, placing strain on your workers’ wrists. Crash lock formats will remove most repetitive wrist motions, making packing work less physically intensive.

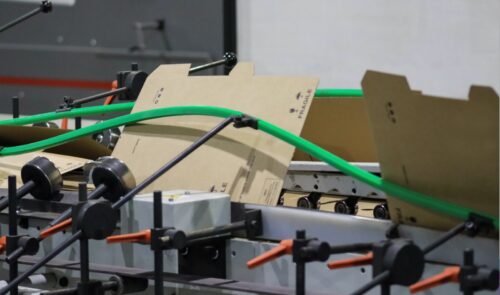

Are Crash Lock Boxes Suitable for Automation?

Crash lock designs are ideal for automated packing lines, and consistent manufacturing is critical for machine uptime. We manufacture all of our packaging in-house using BOBST conversion equipment, which ensures precise cutting and glueing tolerances. Our automation-friendly packaging is specially designed to seamlessly work with case erectors and fully automated box assembly technology to prevent jams when tolerances are maintained, whereas standard boxes with variable tolerances are prone to causing machine stoppages.

How Does Manor Packaging Ensure Your Supply Reliability?

We do not outsource manufacturing. This allows us to retain full control over our quality and lead times, ensuring your packing lines keep moving:

- OTIF Performance: We maintain an On Time In Full (OTIF) delivery rate of 96–98.5%, near-flawless service levels, with a proven track record of reliability.

- Capacity Headroom: We operate with a 30% capacity headroom target throughout the calendar year, which will absorb your demand spikes without delays.

- Supply Chain Security: Our part-ownership of CorrBoard UK provides a gold standard security of supply for our raw materials.

- VPK Group Partnership: VPK Group holds a minority shareholding in the Fencor Packaging Group, which provides access to alternative UK and European production capacity, mitigating the supply chain risks for your business.

Stock and Serve

We manufacture in efficient bulk runs but hold the stock in our own warehouse. If space is at a premium in your fulfilment centre, our stock and serve programme will enable bulk manufacturing with just-in-time delivery, helping you free up warehouse space and reduce your overheads.

Who Benefits Most From Crash Lock Packaging?

The following operations tend to see the fastest return on efficiency from crash lock packaging:

- E-commerce Brands and Brand Owners: Companies focused on the unboxing experience and speed.

- Fulfilment and 3PL centres: Fulfilment houses handling multiple clients and high SKUs.

- Subscription Boxes: Operations requiring uniform presentation and rapid assembly.

- Seasonal Shippers: Businesses with extreme volume spikes, such as Black Friday.

When is a Standard Cardboard Box the right choice?

The standard off the shelf stock box still has its place in packaging solutions, and remains a valid choice for:

- Low Volume: Operations shipping fewer boxes per day.

- B2B Pallet Distribution: Bulk transit where speed and presentation are secondary.

- Static Dimensions: Products requiring fixed-height protection without variable scoring.

Summary

Crash lock boxes assemble four times faster than standard cardboard boxes and eliminate the need for base tape, reducing your labour hours, material costs, and packing time. Crash Lock boxes provide a highly presentable, sustainable, mono-material solution for high-volume operations, a premium pack, which returns greater benefits to the customer.

Review your packing efficiency.

Manor Packaging can audit your current packing process and calculate the time and material savings that introducing a crash lock format would provide your business.

Speak to our packaging specialists to request a sample or book a consultation.